Forward

This standard specifies, based on the production

features of pigskins, hides, sheep/goat skins, the requirements for Eco-Leather

Mark. They are as follows:

1. It sets the specifications for four restricted

substances possibly present in leathers, such as Hexavalent-chromium, Azo

Colourants, Pentachlorophenol (PCP) and Formaldehyde, on top of the general

specifications for physical testing and chemical analysis. The objective of

this is to bring in line the Chinese leather industry with the current

international practice.

2. The specifications and testing methods for general

physical testing and chemical analysis should comply with any relevant ones of

China National or Leather Industry Quality Standards for leather and leather

products. Sampling of leather should follow QB/T2706. The specifications and

testing methods for special chemicals analysis (mentioned above) should follow

current international standards. Sampling should be carried out in accordance

with provision5.2.1. of this ‘Standard’.

1 Scope

This standard prescribes on classification,

requirements, testing method, specifications, labeling, packaging, transportation,

and storage for all kinds of leather qualified Eco-Leather Mark.

This standard applies to leathers of different tannage

used for the production of all kinds of leathers such as furniture, garments,

sole and shoe lining, automotive and glove etc.

2 Normative

references

This specification incorporates by dated or undated

references, which are cited at the appropriate places in the text and the

publications are listed hereafter. For dated references, subsequent amendments

to or revisions of any of these publications apply to this specification only

when incorporated in them by amendment or revision. For undated references the

latest edition of the publication referred to applies. New national or

industrial

standard of other kinds of leather released in

future will also be applicable to this specification if such kinds of leather are

involved in the scope of Eco-Leather Mark.

GB/T 4694 Packaging,

Marking, Transporting, and storing of Finished Leather

GB/T 16799 Furniture

Leather

QB/T 1872 Garment

Leather

QB/T 1873 Upper

Leather

QB/T 2001 Sole

Leather

QB/T 2680 Lining Leather

QB/T 2703 Automotive

Upholstery Leather

QB/T 2704 Glove Leather

ISO 17070 Leather-Chemical

tests-Determination of Pentachlorophenol in leather

ISO 17226 Leather-Chemical

tests-Determination of formaldehyde content in leather

ISO 17234 Leather-Chemical

tests-Determination of certain azo colourants in dyed leather

ISO 17075 Photometric

Determination of chromium (VI) using 1, 5 - Diphenylcarbazide

3

Classification of leather

Classification of leather should be in accordance to relevant

requirements in China National or Leather Industrial standards such as GB/T16799,

QB/T1872, QB/T1873, QB/T2001, QB/T2680, QB/T2703, QB/T2704, etc..

4 Requirements

4.1 General requirements for physical and chemical indexes

The general requirements for physical and chemical

indexes for leather qualified Eco-leather Mark should comply with that of National

or Leather Industrial standards such as GB/T16799, QB/T1872, QB/T1873,

QB/T2001, QB/T2680, QB/T2703, QB/T2704, etc..

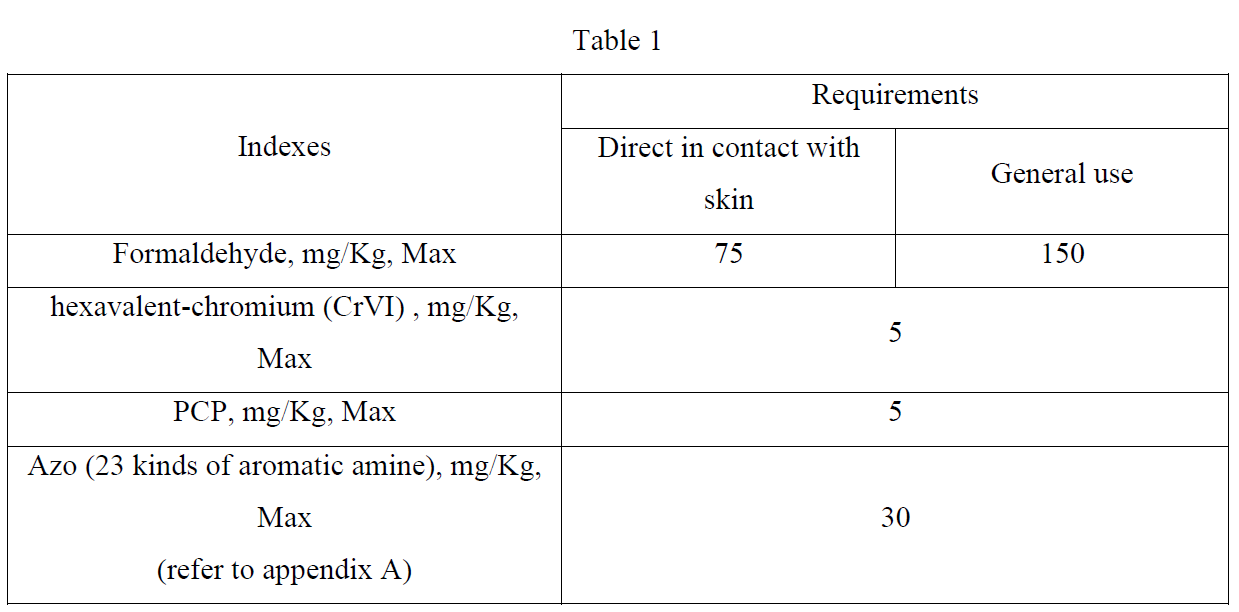

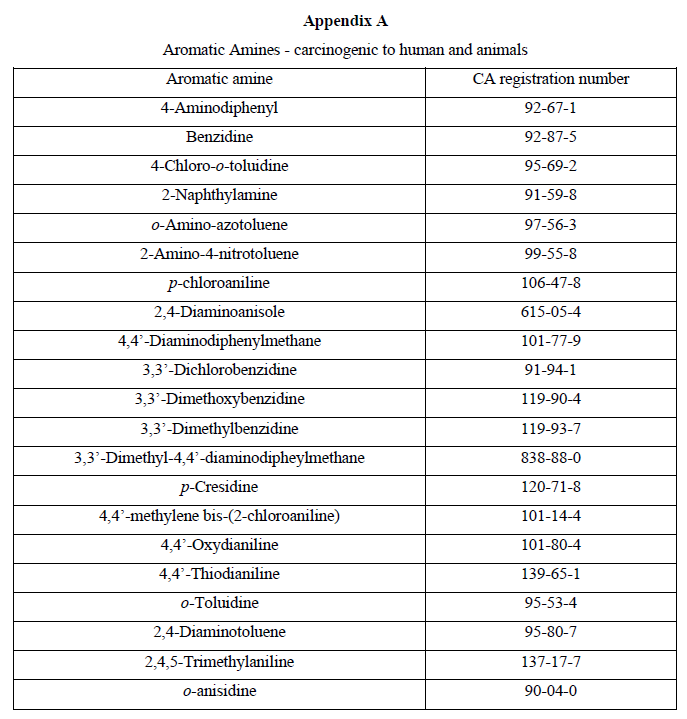

4.2 Special chemicals

indexes

Special chemical indexes should comply with the limits

listed in Table 1.

5 Testing

methods

5.1 General physical and chemical indexes

The test for general physical and chemical indexes should

be carried out according to the standards of GB/T16799, QB/T1872, QB/T1873,

QB/T2001, QB/T2680, QB/T2703, QB/T2704, etc..

5.2 Special chemical indexes

5.2.1Sampling

Cuttings of finished leather should be taken from the

belly area no less than20cmx25cm2.

5.2.2Test method for PCP

This should be carried out under ISO 17070.

5.2.3Test method of formaldehyde

This should be carried out under ISO 17226.

5.2.4Test method of azo

colourants

This should be carried out under ISO 17234.

5.2.5Test method of hexavalent

chromium

This should be carried out under ISO 17075.

6 Specifications

6.1 General physical and chemical indexes

Group and batch sample tests for above should follow

specification and requirements stated in the China National or Leather

Industrial standards such as GB/T 16799, QB/T 1872 and QB/T 1873, etc..

6.2 Special chemical indexes

After being tested under provision 6.1, the leather

samples will further be analyzed for the four restricted chemicals, such as

PCP, Formaldehyde, Chromium VI and AZO dye’s, during which a mixture of the

same quantity of different leather samples are analyzed. The leathers will be

awarded Eco-Leather Mark when their test results are within the range of the

figures detailed in Table 1.

6.3 Routine inspection

6.3.1Following situations will

attract routine inspection

a) Significant change in the production or

process/formula;

b) Re-start of the production after a period of

non-performance;

<

c) Under the request of local supervised bodies;

d) Annual routine inspection.

6.3.2Quantity of samples

Three pieces of leather samples will be taken from

each batch of production.

6.3.3Verification

6.3.3.1 Verification of a

single piece of leather

Leather sample will be judged against the

specifications for fingerprint test, general physical and chemical testing of

China National and Industrial leather standards such as GB/T16799, QB/T1872, QB/T1873,

etc.. The samples will be subject to further testing for its special chemical

contents (the four restricted chemicals).

Should the leather fail any one of the items against

the requirement in the specifications of this standard (Table 1), but it passes

the test for general physical and chemical testing, the leather is to be

retested. If it fails for the second time, the leather will be deemed as a

failure.

6.3.3.2 Verification of batch

leathers

Leather samples will be judged against the

specifications of fingerprint test, general physical and chemical testing of

China National or Industrial leather standards, such as GB/T16799, QB/T1872, QB/T1873,

etc.. The samples will be subject to further testing for their special chemical

contents (such as the four restricted substances).

Should the leathers fail in any one of the items

against the requirement in the specifications of this standard (Table 1), but

they pass the test for general physical and chemical testing, the leathers are

to be retested with increased sample quantity of 6 pieces. If they fail for the

second time, the batch of leathers will be deemed as unqualified.

7 Packaging,

labeling, transportation and storage

Packaging, labeling, transportation and storage should

comply with national standards GB/T4694. In addition, Logo of Eco-Leather Mark

may be stamped on the right hand side,

on the flesh, of each piece of leather. It may also be stamped on

the package of the finished leathers.

Editor’s Note

As a member, China is striving to pursue its

obligation to the World Trade Organization (WTO).

China Leather Industry Association (CLIA), after years

of culmination, officially launched Eco-Leather Mark in 2002, with the

objective, to harness the general awareness of environmental protection, to

increase the competitiveness of Chinese leather products in the global market,

and at the same time, to raise standards and imposing self-discipline.

There are two official documents relating to this program:

one is Specified Standard on Eco-Leather

Mark (Referred to as Standard thereafter), the other is Detailed Regulations on Eco-Leather Mark (Referred to as ‘Regulations’

thereafter)

The official trademark of Genuine Leather Mark

(referred to as ‘GLM’ thereafter), registered at the State Administration for

Industry and Commerce in 1994 by CLIA, leather and fur as well as products

produced from them were included in the scope of this official trademark. However,

in the market, the GLM is used for products made by leather or fur, and

Eco-Leather Mark, which is originated from CLM and stressed on the four special chemical indexes including formaldehyde,

hexavalent chrome, pentachloraphenal (PCP) and azo colourants, is used

for finished leather.

The ‘Regulations’ was initially drafted in 1996 and

being studied and revised several times. In 1998, CLIA officially introduced

the concept of Eco-Leather during a ‘Seminar

on Environmental Protection for Tanners’ held by UNIDO in Beijing,

and praises by the UNIDO officials. In 2000, CLIA presented ‘Eco-Leather Mark’

at the International Environmental Protection Conference sponsored by UNIDO in

Morocco, and received overwhelming support by the participants. The ‘Regulations’

was officially submitted for verification to four sub-committee meetings of

CLIA held in Beijing in June 2002. During the Third Session of the Fourth

Annual Congress of CLIA held in Shanghai in September 2001, the ‘Regulations’

was officially announced to the leather industry.

In 2000, meanwhile, the editorial team of CLIA started

to draft ‘Standard’, and completed its first draft in October 2001. This was

then submitted for discussion and verification to the1st Seminar on China

Leather Technology in the 21st Century, during which many

professionals, and leather experts, from nine leather institutes, including

Universities and colleges, nationwide, offer valuable suggestions and

additional comments.

All participants uniformly endorsed the Standard as of

vital importance to China to achieve its ambition of becoming a leather

superpower, and at the same time to culture a brand new image of Chinese

leather products in the global market.

The draft Standard was eventually completed, thanks to

the support of many experts in leather industry. It was later sent to many organizations,

including sub-committees of CLIA, major tanneries, leather research institutes

and testing houses, for further proof reading and verification. The Standard

was finally submitted and approved by the National Tanners Summit in

June 2002.

Having adopted the current international testing

requirements for leather industry, the editorial team of Standards has, at the

same time, taken into account of the current situation of the Chinese tanning

industry in the production of hides, pig and sheep skins, the consumer

requirements, and its current domestic testing standards. The final provisions

of the Standards included not only the existing physical and chemical testing standards,

but also the limits on certain possible harmful substances existing in leather.

Following are the additional comments on provisions:

1. The Standard were first introduced in 2002 and

further verified and updated in2006

inorder to keep its latest form.

2. General physical testing standards are written in

accordance to the China national or industrial standards such as GB/T 16799,

QB/T 1872, QB/T 1873, and QB/T 2001. QB/T 2680. QB/T 2703, QB/T 2704, etc.

3. Based on the natural structure of leathers and

manufacturing characteristics, the Standard has set specifications for the four

harmful substances such as Chromium VI, Azo Dyes, Formaldehyde and PCP. Being a

member of WTO, China has obligation to follow current international practice.

International Standards Organization (ISO) has published testing methods for

these four chemicals in recent years, such as ISO FDIS 17070, which is the

internationally recognized standard for testing PCP. However, the Standard

states that national recognized testing method is to be applied simultaneously

in China, to compliment the ISO FDSI17070 testing method, which occasionally

produces inconsistent testing results. For the testing of chromium VI, the

Standard allows the use of widely recognized test methods such as IUC 19, 1997,

as ISO DIS 17075 is still not been officially recognized. Once it is approved

by the IUC, it will be adopted by the Standard immediately. The testing of Azo

Dyes and Formaldehyde will follow both ISO testing methods ISO TS17226 and ISO

TS17234.

4. The specifications for the four restricted

substance Chromium VI, Azo Dyes, Formaldehyde and PCP were set as the result of

years of work by CLIA, which has consulted many of the world’s leading test

houses such as BLC Leather Technology Centre in the United Kingdom. At the same

time, CLIA initiated a campaign to establish a picture of current Chinese leather

industry, through the nationwide sample collection and testing (62 leather

samples from 43 major tanneries in China were collected and tested). All this

was aimed to deliver Standard meeting the requirements of leather buyers

worldwide.

5. The testing methods in the ‘Standard’ are the most

updated, and comply with current international practiced.

During the writing of the Standard, the editorial team

of CLIA has received wide support from many organizations. CLIA, hereby, would

like to thank the following organizations for their contribution and support

towards the completion of the Standard:

National Leather Standardization Technical Committee

Tanners’ Committee of CLIA

Science and Technology Commission of CLIA

China Leather and footwear Industry Research Institute

Sichuan University

Shaanxi University of Science and Technology

Shandong Light Industry Institute

State Leather Quality Supervision and Testing Center

National Leather Product Quality Supervision and

testing Center

ITS Shanghai

UNIDO

BLC Leather Technology Centre Ltd.

Leather Institute Germany (LGR)

As well as many leather experts from tanneries and

leather goods manufacturers in China

China Leather Industry Association

Editorial team of Specified

Standard on Eco-Leather Mark

October 2011